In the spin cycle towards sustainability: MPI team achieves mechanochemical production of Ibuprofen Co-Crystals at kilogram scale

Drum mill technology as a step towards green chemistry

Ibuprofen is one of the most widely used pain relievers globally, serving not only to alleviate pain but also to reduce inflammation and fever. Its significance is reflected in its high sales figures and its inclusion on the World Health Organization (WHO) List of Essential Medicines. Given the versatility and high demand for ibuprofen and its various formulations, the efficient and sustainable production of the active ingredient and its derivatives is a central aspect for industry and research. A team led by the Felderhoff group at the Max-Planck-Institut für Kohlenforschung (MPI) has achieved a major breakthrough in the environmentally friendly production of ibuprofen co-crystals by employing a drum mill. The study was published in the journal RSC Mechanochemistry.

Pharmaceutical drugs are mixtures of substances that include the active pharmaceutical ingredient (API) along with other compounds that influence the drug's efficacy, production and performance. For example, the API ibuprofen is heat-sensitive and poorly water-soluble, which poses challenges for its absorption in the body. To enhance water solubility and efficacy, ibuprofen is combined with a partner substance like nicotinamide to form a co-crystal with the desired properties. The research group led by Dr. Michael Felderhoff has now introduced a novel mechanochemical method to efficiently and sustainably produce the ibuprofen co-crystal rac-ibuprofen:nicotinamide at a large scale. The study, headed by Dr. Jan-Hendrik Schöbel, is part of the IMPACTIVE project and utilized an industrial drum mill for the investigation.

Jan-Hendrik Schöbel explains: “We were aware of the potential to produce rac-ibuprofen:nicotinamide using so-called eccentric vibratory mills, which served as a starting point for our research. Our aim was to test further scaling and determine whether the co-crystal could be efficiently produced in larger quantities in drum mills. Drum mills offer significantly higher capacity and better energy efficiency. Moreover, they are widely available in industrial settings but have not yet been employed for the production of co-crystals and other pharmaceuticals.”

How the drum mill works: A washing machine-inspired method delivering impressive results

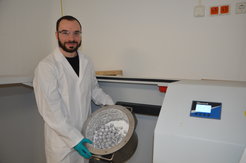

Drum mills are industrial machines used to process granulates and powders by grinding. Their operating principle is similar to that of a washing machine: instead of water, stainless steel balls are used, and instead of dirty laundry, dry materials are processed.

In this newly introduced process, the method of liquid-assisted grinding (LAG) proved particularly successful. Ibuprofen and nicotinamide were ground together with a small amount of solvent and stainless steel balls. Under optimized parameters, the co-crystal could be synthesized in just 90 minutes with a 99% yield—a much faster and more resource-efficient method compared to traditional solvent-based synthesis. The resulting product exhibited excellent quality, with high purity and stability. Metal contamination from the grinding process was minimal, well below regulatory limits for pharmaceutical consumption. Furthermore, over 3 kg of the co-crystal were successfully produced.

“We believe that drum milling holds significant promise. It could potentially revolutionize the industrial production of co-crystals and pharmaceuticals by accelerating manufacturing processes and reducing environmental impact,” says Jan-Hendrik Schöbel. The study demonstrated success at the kilogram scale, and there is now an opportunity to evaluate drum mill-based mechanochemical grinding for the synthesis of other active pharmaceutical ingredients (APIs).

About IMPACTIVE

Since 2022, Dr. Michael Felderhoff's group has been part of the European large-scale research project Impactive (Innovative Mechanochemical Processes to Synthesize Green ACTIVE Pharmaceutical Ingredients). This initiative focuses on developing pharmaceutical production methods through mechanochemistry. Mechanochemistry is considered an environmentally friendly and cost-effective approach, as its processes largely avoid solvents, are energy-efficient, and reduce costs. The current project phase aims to scale mechanochemical methods for large-scale industrial applications.

Link to the publication:

Jan-Hendrik Schöbel et al., "Mechanochemical kilogram-scale synthesis of rac-ibuprofen:nicotinamide co-crystals using a drum mill," RSC Mechanochemistry (2024). DOI: 10.1039/D4MR00096J